Equipment as Smart as the Materials Themselves

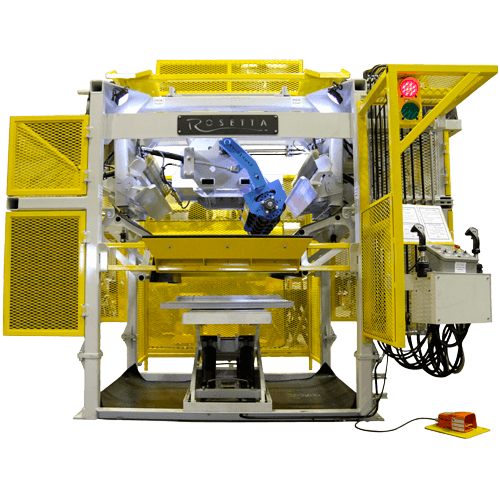

Just like the unique outdoor living spaces they create, producing Rosetta Hardscapes isn’t a one-size-fits-all proposition. You’ll maintain production versatility with intelligent manufacturing systems and processes designed with scalability in mind.

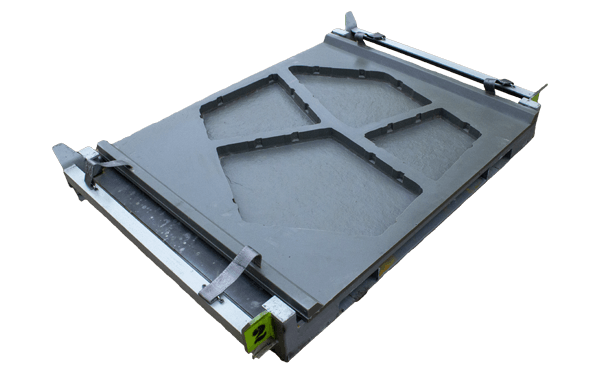

Auxiliary Equipment

In addition to forms and molds, auxiliary equipment can expedite production from start to finish.

Forklift with 360 Degree Form Rotator

For demolding and palletizing, you’ll need a dedicated forklift and 360-degree rotator attachment with rubber fork protectors. The rotor attachment is available only through Rosetta Hardscapes.

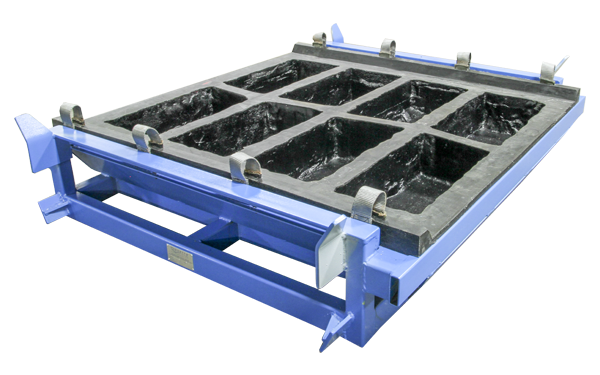

Vibrating Table

Available through Rosetta or sourced through other suppliers, a vibrating table ensures the concrete is consolidated to achieve a better consistency before curing.

Concrete Conveyance System and Sprayers

Release agent sprayers produce easier demolding after curing is complete. Buckets and roller lines help efficiently move the poured forms.

Packaging

Demolding and step stations aid palletizing and finished packaging of the products and a heat gun ensures plastic wrap secures the products.

Licensing Always Ensures a Leg Up

When you license Rosetta Hardscapes, you unlock a powerful business growth and diversification engine. Rosetta is a whole lot more than just the proprietary forms and molds. You’ll have the backing of a team of industry experts invested in your success, innovators continually working to improve production equipment and processes and developing new and impactful products for your market.

Equipment Packages

The beauty of Rosetta is, well… its beauty. But scalability and customization can also be beautiful things. We’ll work with you to build an equipment arrangement tailored to your very specific needs. So give some thought to the type of customer you’d prefer to work with initially. Your vision can help us dial in the best equipment package for your launch.

Retaining Wall Packages

Is working with engineers, specifiers, and retaining wall contractors right up your alley? We can help you build the perfect way to get started providing your market with beautiful hardscapes.

Patio Packages

If you prefer to help landscape architects and contractors create beautiful outdoor residential and commercial relaxation spaces, a patio package might be for you

Vision

Tell us a little about how you want to put Rosetta Hardscapes to work for you and we’ll generate some recommendations tailored just for you.

FAQ

How much money should I plan to invest to produce Rosetta Hardscapes products?

Many factors play into the cost of licensing and producing Rosetta Hardscapes, including the geographic market you'd like to produce within, the specific produts you'd prefer to manufacture, equipment you may already own, the profit you'd like to clear, and more. We can share that all-inclusive start-up patio packages generally begin around $265,000. That includes forms and equipment for making Rosetta. What is not covered is a dedicated forklift and means of attaining concrete.

What are my equipment options as a producer?

Equipment options vary from low-tech, manual labor-based processes up to semi-automated assembly line-style configurations. Start with a forklift, your Rosetta forms, and a means of pouring concrete, then grow into a more hands-off production system. Automation (and the time and labor savings it generates) is employed primarily in the pouring line segment of production currently, but regular equipment and process advances continue to be made, ensuring Rosetta production is some of the most automated manufacturing in the industry.

How long will my forms last?

Form and mold lifespans depend upon the level of use and how they're maintained. Just like any piece of manufacturing equipment, the better it's cared for, the longer it will last. Rosetta's provides comprehensive tested recommendations for care and maintenance to ensure the longest lifetime of all forms and molds. Following these recommendations closely should result in your high-use rubber molds enjoying a 3-9 year life span and steel forms producing Rosetta Hardscapes products for 15-20 years.

What forms should I buy?

Your initial form investment should be based almost entirely on the products your market space currently demands. Will you supply a hilly region that demands retaining and landscape walls to maximize outdoor space? How about an area where most homes feature outdoor pools so patios become important amenities? We can help you determine a product selection that positions you for success, both short- and long-term.